Mini ekskavatörler, birçok inşaat ve mühendislik projesinde olmazsa olmaz ekipmanlardır. Çeşitli çalışma ortamlarında en iyi performansı göstermelerini sağlamak için düzenli bakım ve onarım şarttır. GFM ekskavatör parça üreticileri Günlük muayenelerden uzun vadeli bakıma kadar her şeyi kapsayan kapsamlı bir "Mini Ekskavatör Bakım Kılavuzu" sunarak ekipman arızalarını azaltmanıza, iş verimliliğinizi artırmanıza ve uzun vadeli işletme maliyetlerinizi düşürmenize yardımcı oluyoruz.

Mini Ekskavatörünüzün Optimum Verimlilikte Çalışmasını Sağlamak İçin Kılavuz

Mini ekskavatörünüzün inşaat sırasında optimum verimliliğini korumasını sağlamak için en önemli şey, onarımları sürekli olarak takip etmek ve zamanında gerçekleştirmektir. Verimli çalışmasını sağlamak için birkaç ipucu:

- Hidrolik sisteminizi düzenli olarak kontrol edin: Hidrolik sistem, küçük ekskavatörün kalbidir. Hidrolik yağ seviyesinin ve yağ kalitesinin gerekliliklere uygun olduğundan emin olun. Hidrolik yağın düzenli olarak değiştirilmesi, hidrolik sistem arızalarını önleyebilir.

- Motor performansını kontrol edin: Motorun uygun çalışma sıcaklığını koruması gerekir. Sızıntı veya tıkanıklık olmadığından emin olmak için soğutma sistemini ve radyatörü düzenli olarak kontrol edin.

- Yağlama sistemi muayenesi: Her hareketli parçanın yağlanması sürtünmeyi azaltabilir, mekanik verimliliği artırabilir ve gereksiz aşınmayı önleyebilir.

Çalışmaya başlamadan önce

Her çalışmadan önce, ekskavatörün temel fonksiyonlarını ve güvenlik ayarlarını kontrol etmek çok önemlidir. Çalışma sırasında arızaları önlemek için tüm parçaların düzgün çalıştığından emin olun.

- Yakıt ve yağı kontrol edin: Yakıt ve hidrolik yağının yeterli olduğundan emin olun ve yağın kalitesini kontrol edin.

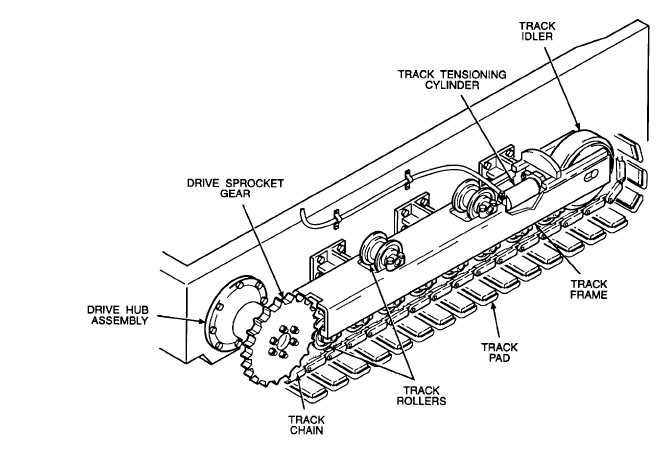

- Palet ve şasiyi kontrol edin: Paletin hasarlı veya gevşek olup olmadığını kontrol edin ve şasinin temiz ve kalıntılardan arınmış olduğundan emin olun.

- Motor ve soğutma sistemini kontrol edin: Motor soğutma suyunun yeterli olup olmadığını kontrol edin ve radyatörün tıkalı olmadığından emin olun.

- Çalışma ışıklarını ve gösterge panelini kontrol edin: Çalışma esnasında hata yapmamak için çalışma lambaları, ikaz lambaları, gösterge panelleri vb.'nin normal çalıştığından emin olun.

Çalışmaya başlamaya hazır olduğunuzda

Çalışmaya başlarken ön incelemenin yanı sıra aşağıdaki hususlara özellikle dikkat etmeniz gerekir:

- Çalışma modunu ayarlayın: Farklı çalışma görevleri farklı çalışma modları gerektirebilir. Çalışma verimliliğinizi artırmak için doğru modu seçtiğinizden emin olun.

- Makul bir iş yükü belirleyin: Özellikle yumuşak topraklarda veya engebeli arazilerde çalışırken ekskavatörü aşırı yüklemekten kaçının. Aşırı yük, makinenin aşınmasını hızlandıracaktır.

Ekskavatörün proaktif bakımı

Proaktif bakım, arıza olasılığını önemli ölçüde azaltabilir ve makinenin kullanım ömrünü uzatabilir. Makinenin düzenli temizliği, bağlantı yerlerinin yağlanması ve önemli parçaların muayenesi günlük bakımın anahtarıdır.

- Ekipmanların düzenli temizliği: Makinenin temizlenmesi, çamur ve toz gibi kirleri etkili bir şekilde temizleyebilir ve mekanik parçalardaki aşınmayı azaltabilir.

- Aşınan parçaları kontrol edin ve değiştirin: Lastik, palet, conta gibi aşınan parçalar düzenli olarak kontrol edilmeli ve zamanında değiştirilmelidir.

Düzenli bakım prosedürlerini takip edin

Düzenli bakım, küçük ekskavatörlerin uzun vadeli ve istikrarlı çalışmasının temelini oluşturur. Her küçük ekskavatör, üretici tarafından sağlanan bakım kılavuzuna uymalı ve önerilen bakım döngüsüne göre bakım yapmalıdır. Yaygın bakım öğeleri şunlardır:

- Motor yağını ve filtresini değiştirin: Motor yağı ve filtresinin düzenli olarak değiştirilmesi, motoru etkili bir şekilde koruyabilir ve yakıt verimliliğini artırabilir.

- Hava filtresini kontrol edin ve değiştirin: Motor sistemine toz girmesini önlemek için motor hava filtresinin temiz olduğundan emin olun.

- Yakıt sistemini kontrol edin: Yakıt hattını düzenli olarak kontrol ederek sızıntı olmadığından ve yağ pompasının düzgün çalıştığından emin olun.

Aşağıda önerilen servis aralıkları verilmiştir

Farklı ekskavatör bakım servis aralıkları farklılık gösterebilir. Yaygın bakım öğeleri için önerilen bazı aralıklar şunlardır:

- Her 100 saatte bir: Hidrolik yağını ve yağ seviyesini kontrol edin, hidrolik yağ filtresini kontrol edin.

- Her 250 saatte bir: Motor yağını ve filtresini değiştirin, yakıt sistemini kontrol edin.

- Her 500 saatte: Palet gerginliğini kontrol edin ve soğutma sistemini temizleyin.

- Her 1000 saatte: Hidrolik sistemi tamamen kontrol edin, hava filtresini değiştirin ve hidrolik yağ sıcaklığını kontrol edin.

Yaygın ekskavatör bakım sorunları

Ekskavatör bakımında karşılaşılan yaygın sorunlardan bazıları şunlardır:

- Hidrolik sistem arızası: Hidrolik yağ kalitesinin düşük olmasından veya hidrolik filtrenin tıkanmasından kaynaklanabilir.

- Motorun aşırı ısınması: Genellikle soğutma sisteminin tıkanması veya soğutma sıvısının yetersiz olmasından kaynaklanır.

- Ray aşınması: Aşırı kullanım veya zamanında kontrol edilmemesi rayların erken aşınmasına neden olabilir.

Ekskavatör alt takımı için bakım ipuçları

Şasi, küçük bir ekskavatörün önemli bir parçasıdır, özellikle karmaşık arazilerde çalışırken şasi bakımı daha da kritiktir:

- Ray gerginliğini kontrol edin: Rayın çok gevşek veya çok sıkı olmamasına dikkat edin, aksi takdirde ray düşebilir, çok sıkı olması ise aşınmayı hızlandırabilir.

- Şasiyi temizleyin: Özellikle çamurlu ve tozlu ortamlarda her işlemden sonra şaseyi temizleyin.

Mali konular: Ekskavatör işletme giderlerini yönetin

Bir ekskavatörün işletme giderleri; yakıt maliyeti, bakım maliyeti, işçilik maliyeti vb. gibi kalemlerden oluşur. Bu maliyetlerin makul bir şekilde planlanması, işletme maliyetlerinizi düşürmenize yardımcı olacaktır:

- Yakıt tüketimini optimize edin: Makinenizi en iyi çalışma koşullarında tutun ve yakıt israfını önleyin.

- Makul planlama: Uzun süreli boşta kalma veya aşırı kullanımdan kaçınmak için çalışma zamanını makul bir şekilde ayarlayın.

Ekskavatör şasi parçaları satın almak için en iyi ipuçları

Şasi parçaları satın alırken, yüksek kaliteli ve uyumlu ürünler seçtiğinizden emin olun. Aşağıdaki hususlara dikkat etmeniz önerilir:

- Uyumluluk: Satın aldığınız parçaların ekskavatör modelinize uyumlu olduğundan emin olun.

- Kalite güvencesi: Satın aldığınız parçaların uzun ömürlü ve garantili olmasını sağlamak için güvenilir bir tedarikçi seçin.

- Fiyat karşılaştırması: Satın alınan parçaların rekabetçi fiyatlara sahip olduğundan emin olmak için birden fazla tedarikçiyi karşılaştırın.

Satın almadan önce diğer hususlar

Bir ekskavatör veya aksesuarlarını satın alırken aşağıdaki faktörleri de göz önünde bulundurmalısınız:

- Ekipman performansı: Aşırı yatırım yapmaktan kaçınmak için mühendislik ihtiyaçlarınıza uygun ekipmanları seçin.

- Satış sonrası servis: Tedarikçinin teknik danışmanlık, ekipman bakımı vb. gibi satış sonrası tam destek sağlayıp sağlamadığını öğrenin.

- Ekipman güvenilirliği ve dayanıklılığı: Uzun vadeli kullanımda ekipmanın sağlamlığı ve dayanıklılığı yatırım getirinizi belirler.

Düzenli bakım ve özenli bakım, küçük ekskavatörlerin verimli çalışmasını ve uzun ömürlü olmasını sağlamanın anahtarıdır. Yukarıdaki bakım yönergelerini izleyerek, yalnızca ekipman arızalarını azaltmakla kalmaz, aynı zamanda iş verimliliğini artırabilir ve işletme maliyetlerini düşürebilirsiniz. Unutmayın, yalnızca ekipmanın uzun vadeli sağlığına dikkat ederek projenin sorunsuz ilerlemesini sağlayabilir ve daha iyi ekonomik faydalar elde edebilirsiniz.

| Hızlı ve ücretsiz bir teklif alın | E-posta: henry@gfmparts.com | Whatsapp: +86 17705953659 |