Table of contents

Overview of Excavator Track Chains

Excavator track chains are a crucial component of construction machinery, directly affecting traction, stability, and operational efficiency. Whether on construction sites, mining operations, or roadworks, track chains must withstand the machine’s weight and ground impact, ensuring stable performance on challenging terrains. Understanding the structure, working principle, and suitable environments of track chains is essential to extend excavator life and reduce maintenance costs.

Components of Track Chains

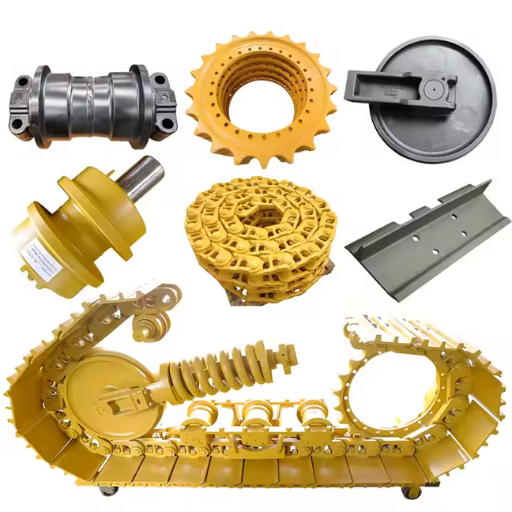

Track chains mainly consist of track plates, pins, bushings, sprockets, and idlers:

- Track plates: Directly contact the ground, support the machine’s weight, and transmit traction.

- Pins and bushings: Connect links and withstand shear and bending stress, critical for chain durability.

- Sprockets and idlers: Maintain track tension and guidance, ensuring smooth excavator movement.

The material quality, heat treatment, and precision of these components directly affect the performance and lifespan of the track chain.

Impact of Operating Environment

Track chain performance depends not only on design and materials but also on environmental conditions. For example, dry and hard surfaces accelerate track plate wear, while muddy or rocky terrains may cause chain link jamming or damage. Choosing the right type of track chain and working with reliable excavator track chain manufacturers or excavator track chain suppliers can effectively enhance machine durability and operational efficiency.

Dry Track Chains: Structure, Advantages, and Applications

Dry track chains are a simple type of chain without internal lubrication, relying on metal friction between links to transmit motion.

Structure of Dry Track Chains

Dry chains are made of high-strength alloy steel track plates, heat-treated pins, and wear-resistant bushings, with external links exposed and direct contact between track plates and pins. Precision heat treatment allows dry chains to maintain good wear resistance under high load and reduce mechanical failures.

Advantages of Dry Track Chains

- Simple structure and easy maintenance: No internal lubrication required, reducing daily maintenance costs.

- Strong adaptability to harsh environments: Resistant to clogging or contamination in mud, sand, or cement environments.

- Lower cost: Simpler production process and generally more affordable than lubricated chains.

Limitations of Dry Track Chains

- Faster wear: Lack of internal lubrication causes link wear over time.

- Limited impact resistance: High load or prolonged operation may lead to chain fatigue or damage.

Applications of Dry Track Chains

Dry chains are suitable for light or medium excavators and dry, hard ground environments, such as construction sites, roadwork, or gravel yards. Their simple and reliable design makes daily inspection and maintenance easier.

Lubricated Track Chains: Structure, Advantages, and Applications

Lubricated track chains have internal oil lubrication between pins and bushings, suitable for medium to large excavators and high-load operations, significantly extending chain life and reducing downtime.

Internal Design of Lubricated Chains

Lubricated chains use high-viscosity oil between pins and bushings, providing continuous lubrication during movement and reducing metal friction. The chains usually feature external dust covers to prevent dirt, mud, and debris from entering the links and protect the internal lubrication system.

Advantages of Lubricated Chains

- High wear resistance: Internal lubrication reduces friction, prolonging chain life.

- Strong impact resistance: Suitable for high-load, continuous operations, minimizing fatigue and damage.

- Long maintenance intervals: Lubrication keeps the links in good condition, reducing routine maintenance.

Limitations of Lubricated Chains

- Complex structure and higher cost: Manufacturing process is more complex and more expensive than dry chains.

- Environment sensitivity: In dusty or muddy conditions, dust cover sealing must be ensured to avoid lubricant contamination.

Applications of Lubricated Chains

Lubricated chains are ideal for large-scale mining, tunnel construction, and heavy-duty earthmoving operations, ensuring reliability and long service life under high-intensity workloads.

How to Choose the Right Track Chain for Your Excavator

Choosing a track chain requires considering the operating environment, machine load, and chain specifications to ensure stable operation and extend service life.

1. Analyze the Working Environment

- Dry and hard surfaces: Dry chains are more suitable, simple, dust-resistant, and easy to maintain.

- Muddy, slippery, or rocky terrains: Lubricated chains reduce wear and improve impact resistance.

- Mixed or frequently changing terrains: Choose the chain type based on workload, using lubricated chains when higher durability is needed.

2. Consider Machine Load and Operating Intensity

- Light excavators (5–15 tons): Dry chains are adequate, easy to maintain and cost-effective.

- Medium to large excavators (20–50 tons): Lubricated chains are preferred for high load and continuous operation.

- Heavy-duty or continuous operation machines: Lubricated chains are the best choice, paying attention to chain strength, pin hardness, and plate thickness.

3. Confirm Machine Model and Chain Specifications

Different brands and models have varying chain specifications, including track plate width, pin diameter, number of links, and sprocket size. Check the model and parameters carefully to ensure compatibility. GFM provides track chains covering mainstream brands (Komatsu, Hitachi, Caterpillar, Volvo, Kobelco, Daewoo, Doosan, Hyundai, Kubota, Bobcat, Yanmar, SANY, Liugong, XCMG, Shantui, etc.), meeting different machine requirements.

Core Advantages of GFM Excavator Track Chains

GFM has been specializing in the production of undercarriage parts for excavators and bulldozers since 2011, including track chains, track plates, carrier rollers, sprockets, idlers, bolts, nuts, pins, bushings, and other accessories. With 14 years of professional experience and modern factory facilities, GFM track chains have the following core advantages:

- High-Quality Materials and Advanced Technology: GFM strictly selects high-quality alloy steel and combines casting, forging, and comprehensive heat treatment processes to ensure each track chain maintains wear resistance and strength under high load and complex working environments. Every product undergoes strict quality inspection before leaving the factory, meeting or exceeding industry standards.

- Extensive Compatibility: GFM track chains are compatible with multiple mainstream brands, including Komatsu, Hitachi, Caterpillar, Volvo, Kobelco, Daewoo, Doosan, Hyundai, Kubota, Bobcat, Yanmar, SANY, Liugong, XCMG, Shantui, etc. Regardless of the equipment brand, customers can get directly matched chains, avoiding compatibility issues.

- Sufficient Stock and Fast Delivery: GFM has mature production lines and sufficient stock to handle large orders and ensure timely delivery of track chains and other undercarriage parts for domestic and international customers, keeping projects on schedule.

- Reliable Product Quality and Warranty: GFM provides a minimum one-year or 2,000-hour warranty for all track chains, ensuring full support during use. High reliability and strict factory standards make GFM a trusted source of spare parts.

- Competitive Pricing and Bulk Supply: Through factory-direct sales and efficient production management, GFM offers competitive pricing and the capability to handle large-scale orders, providing high cost-performance solutions to customers.

- Industry Experience and Customer Trust: With 14 years of experience in undercarriage parts manufacturing, GFM’s team understands various operating environments and machine requirements, offering professional advice and after-sales support. GFM has supplied parts for numerous domestic and international projects, earning long-term customer trust.

| Get a quick free quote | Email: henry@gfmparts.com | Whatsapp: +86 17705953659 |

Dry and lubricated track chains each have their advantages. Dry chains are simple and cost-effective, suitable for dry or light-duty environments; lubricated chains offer high wear resistance and long service life, ideal for heavy-duty and complex working conditions. Selecting the right track chain type and working with reliable excavator track chain manufacturers and excavator track chain suppliers ensures higher operational efficiency and longer equipment lifespan. GFM, with high-quality materials, advanced technology, and extensive stock, provides high-performance track chains and undercarriage parts, making it a trusted long-term partner.