Daftar isi

Keunggulan Industri dan Pengalaman Manufaktur GFM

Didirikan pada tahun 2011, Quanzhou Ganfeng Machinery Co., Ltd. (GFM) telah berkembang menjadi perusahaan yang sangat berpengalaman produsen suku cadang undercarriage ekskavatorGFM berspesialisasi dalam memproduksi suku cadang untuk ekskavator dan buldoser, dengan fokus khusus pada komponen undercarriage. Selama 14 tahun terakhir, GFM terus menyempurnakan proses produksi dan kualitas produknya, sehingga mendapatkan kepercayaan dari klien di seluruh dunia.

Fasilitas Produksi Modern dan Skala

GFM mengoperasikan pabrik modern yang dilengkapi dengan mesin canggih dan peralatan inspeksi kualitas untuk memastikan produksi komponen teknik presisi yang memenuhi standar industri tertinggi. Lini produksinya meliputi peralatan pengecoran dan penempaan, tungku perlakuan panas, dan instrumen inspeksi presisi. Pengaturan ini memungkinkan GFM untuk menangani pesanan massal dan proyek khusus secara efisien, sekaligus menjaga stok yang cukup untuk memenuhi kebutuhan pelanggan domestik dan internasional.

Lini Produk Komprehensif dan Kompatibilitas Merek

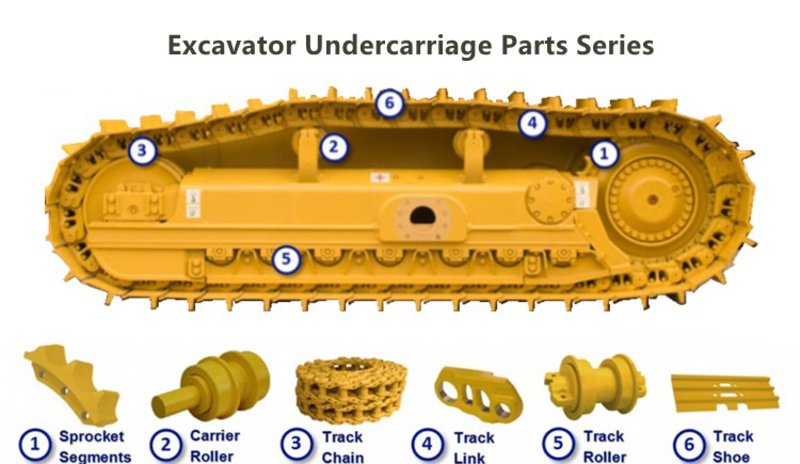

GFM menawarkan berbagai macam bagian undercarriage excavator, termasuk:

- Rol pembawa, rol lintasan, idler, sproket, roda penggerak

- Sepatu lintasan, rantai lintasan, rakitan lintasan lengkap

- Baut, mur, pin, bushing

- Ember dan gigi ember

Komponen-komponen ini kompatibel dengan sebagian besar merek ternama, seperti Komatsu, Hitachi, Caterpillar, Volvo, Kobelco, Daewoo, Doosan, Hyundai, Kubota, Bobcat, Yanmar, Sany, Liugong, XCMG, dan Shantui. Dengan kompatibilitas yang luas dan pilihan produk yang beragam, GFM menyediakan solusi terpadu yang praktis untuk kebutuhan undercarriage pelanggan.

Jaminan Kualitas dan Kepercayaan Pelanggan

GFM menjamin kualitas produk 100% untuk setiap komponen dan memberikan masa garansi minimal satu tahun atau 2.000 jam operasional. Setiap komponen menjalani inspeksi ketat, termasuk akurasi dimensi, kekerasan material, dan uji kinerja keseluruhan, untuk memastikannya memenuhi atau melampaui standar industri. Komitmen terhadap kualitas ini telah membantu GFM meraih reputasi yang kuat di antara pelanggan di seluruh dunia.

Komponen Inti dan Fungsi Bagian Undercarriage Excavator

Komponen undercarriage merupakan fondasi operasional ekskavator. Kinerjanya secara langsung memengaruhi stabilitas, mobilitas, dan masa pakai alat berat. GFM menyediakan rangkaian lengkap suku cadang undercarriage ekskavator, masing-masing dengan fungsi yang jelas.

- Rol: Rol dibagi menjadi rol pembawa dan rol lintasan. Rol pembawa menopang berat mesin dan mendistribusikan tekanan tanah, sementara rol lintasan menopang lintasan atas dan mempertahankan tegangan lintasan. GFM memproduksi rol dari baja berkualitas tinggi dan menerapkan perlakuan panas untuk meningkatkan ketahanan aus dan ketangguhan, memastikan kinerja yang stabil dalam penggunaan jangka panjang.

- Pemalas: Terletak di bagian depan rel, idler memandu rel dan menjaga tegangan yang tepat. Idler GFM yang dikerjakan dengan presisi dan diberi perlakuan panas memastikan pengoperasian yang andal dalam berbagai kondisi kerja, sehingga efektif mencegah rel tergelincir atau melonggar.

- Roda Gigi dan Roda Penggerak: Sproket dan roda penggerak merupakan komponen kunci transmisi daya, yang mengubah daya hidrolik menjadi pergerakan rel. Sproket dan roda penggerak GFM terbuat dari baja berkekuatan tinggi, ditempa, dan diberi perlakuan panas untuk meningkatkan ketahanan aus gigi, memastikan transmisi daya yang lancar dan masa pakai yang lebih lama.

- Sepatu Trek, Rantai Trek, dan Rakitan Trek Lengkap: Track shoe bersentuhan langsung dengan tanah, menopang mesin dan beradaptasi dengan medan yang kompleks. Rantai track menghubungkan shoe ke dalam rakitan track yang lengkap, memastikan pergerakan mesin yang mulus. GFM menyediakan sistem track yang dirakit sepenuhnya, ditempa, dan diberi perlakuan panas untuk ketahanan aus, kekuatan tarik, dan ketahanan benturan yang unggul.

- Baut, Mur, Pin, Bushing, dan Gigi Bucket: Selain komponen inti undercarriage, GFM menawarkan satu set lengkap pengencang dan bahan habis pakai pelengkap, termasuk baut, mur, pin, bushing, dan gigi bucket. Semua aksesori dipilih dan diproses dengan cermat untuk memastikan daya tahan dan kompatibilitas, memberikan solusi suku cadang yang lengkap bagi pelanggan.

Manufaktur Presisi dan Kontrol Kualitas

Manajemen produksi GFM yang ketat memastikan keandalan suku cadang undercarriage ekskavatornya.

Pemilihan Material

Semua komponen terbuat dari baja paduan berkekuatan tinggi, dianalisis secara ketat untuk komposisi kimia dan kualitasnya guna memastikan kekerasan, ketangguhan, dan ketahanan aus yang tepat.

Proses Manufaktur Lanjutan

- Pengecoran dan Penempaan:Komponen utama seperti sproket, roda penggerak, dan track shoe ditempa untuk meningkatkan kekuatan.

- Perlakuan Panas: Komponen menjalani pendinginan dan pengerasan suhu tinggi untuk mencapai kekerasan dan ketahanan aus yang optimal.

- Pemesinan Presisi:Pusat permesinan CNC menjaga toleransi dimensi, memastikan kompatibilitas yang sempurna dengan mesin.

Inspeksi dan Kontrol Pabrik

GFM dilengkapi dengan alat uji kekerasan presisi tinggi, mesin pengukur koordinat, dan detektor cacat ultrasonik, yang melakukan inspeksi komprehensif pada setiap komponen. Pengambilan sampel batch acak memastikan semua produk memenuhi standar kinerja dan industri sebelum meninggalkan pabrik.

Masalah Umum dan Solusinya

Bahkan komponen undercarriage ekskavator berkualitas tinggi pun dapat mengalami masalah selama pengoperasian jangka panjang. Memahami masalah ini dan solusinya akan membantu memperpanjang umur peralatan.

Pelonggaran Trek

Menyebabkan: Pemasangan yang tidak tepat atau idler yang aus.

Larutan: Periksa ketegangan rel secara teratur dan sesuaikan menurut spesifikasi; ganti idler yang aus bila diperlukan.

Keausan Berlebihan

Menyebabkan: Kondisi kerja yang keras atau pelumasan yang tidak memadai.

Larutan: Jaga pelumasan roller dan sprocket, gunakan suku cadang GFM berkualitas tinggi, dan hindari kelebihan muatan.

Kerusakan Sproket atau Roda Penggerak

Menyebabkan: Operasi berat yang berkepanjangan atau retak akibat kelelahan.

Larutan: Periksa gigi secara teratur; ganti komponen yang terlihat retak atau aus; kendalikan beban operasional.

Dengan menerapkan langkah-langkah ini, waktu henti peralatan dapat diminimalkan, memastikan pengoperasian ekskavator yang lancar dan efisien.

Kasus Pelanggan dan Pengakuan Industri

Klien Internasional dan Proyek Sukses

Suku cadang GFM banyak digunakan di pasar domestik dan internasional, termasuk Amerika Utara, Eropa, dan Asia Tenggara. Dengan stok yang memadai dan pengiriman yang cepat, klien dapat menerima suku cadang yang dibutuhkan dengan segera, sehingga mesin tetap beroperasi.

Pengakuan Industri

- Produknya bersertifikasi ISO 9001, memenuhi standar industri global.

- GFM berkolaborasi dengan berbagai merek ekskavator untuk memasok komponen OEM, menunjukkan keandalan dan kepercayaan industri.

- Tim profesional dan layanan berkualitas tinggi telah membantu GFM membangun reputasi yang kuat di pasar global.

| Dapatkan penawaran cepat dan gratis | Surel: henry@gfmparts.com | WhatsApp: +86 17705953659 |

Sejak 2011, GFM telah berfokus pada manufaktur suku cadang undercarriage, menggabungkan pengalaman luas, fasilitas modern, dan lini produk yang komprehensif untuk menjadi produsen suku cadang undercarriage ekskavator tepercaya secara global. Baik itu roller pembawa, roller track, idler, sprocket, track shoe, maupun baut dan bushing, GFM menyediakan komponen yang tahan lama, berkinerja tinggi, dan sangat kompatibel.

Memilih GFM berarti mendapatkan suku cadang berkualitas tinggi yang meningkatkan efisiensi peralatan, memperpanjang masa pakai, dan mengurangi biaya perawatan. Dengan tim profesional, dukungan purnajual yang lengkap, dan layanan pelanggan global, GFM terus menghadirkan solusi undercarriage yang andal bagi industri permesinan konstruksi.